Produkt suchen

Produktkategorien

Produkt-Tags

Zuletzt angesehen

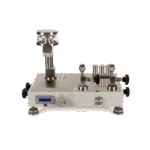

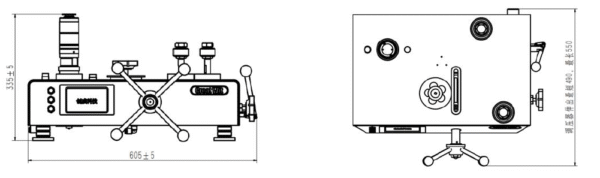

PR Automatic Dead Weight Tester

6, 60, 120, 250, 500MPa

Accuracy: 0.005%

Calibration laboratories

Precision pressure sensor manufacturers

Calibration service companies

Nur englische Version

The gas piston system is processed using automic-level material injection and nanoscale planarization processes, ensuring that the gas piston maintains rotational sensitivity for over 30 consecutive working days. The combination of weights with the required mass can be automatically calculated and loaded, allowing for skip-type loading of any pressure point (corresponding to the weight combination) within the measurement range. The weight loading/unloading time does not exceed 3 seconds.

The pressurization, holding, and release of pressure can be automatically achieved through a single-button operation. The weights can be lifted with a single-button operation, facilitating the disassembly of the piston assembly and ensuring convenience and efficiency.

Parameters such as piston position, piston temperature, and weight rotation speed can be sensed

and displayed in real-time. System errors can be corrected and compensated for by adjusting parameters such as temperature, air buoyancy, and liquid level differences.

All weights rotate synchronously without wear during loading and unloading, ensuring long-term

accuracy of weight measurement. The intelligent control algorithm is employed, resulting in a short stabilization time from pressurization to piston position, and the control system exhibits high robustness.

Check points can be either manually input or automatically generated.

Equipped with expansion interfaces, it offers robust scalability. Safety protection devices are configured, including piston system anti-breakage rod protection, wrong operation protection etc.

Please refer other dimensions in datasheet